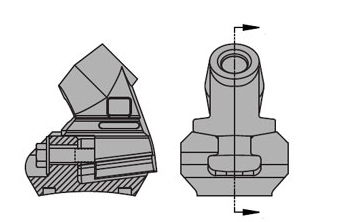

Description

Quick change block systems are designed to make it easier and faster to switch between the tools that you need. In addition to allowing for easy tool exchanges, the block systems also offer a secure hold that will keep tools, equipment and workers safe. If you find yourself frequently switching between machines to get the right application, the quick change block systems will allow you to bring less equipment while still getting the results you are looking for. With two different holder and base designs, you can choose the best quick change block system for your equipment, including a design for machines operating at 400 horsepower or higher and machines operating at less than 400 horsepower.

QC100 Base

- for machines more than 400 horsepower

QC110HD Holder

- for machines more than 400 horsepower

QC110B Base

- for machines less than 400 horsepower

QC110H Holder

- for machines less than 400 horsepower

Reviews

There are no reviews yet.